Just fix the damned potholes!

How we fix potholes in Cambridgeshire, why we still have to, and what we’re doing to get ahead of the problem.

If I had a penny for every time someone told me to fix the potholes, I’d be a rich man (well, at least rich enough for a flat white at Bould Brothers). But here’s the thing: the places with the best roads? They’re not winning because they fix more potholes, they’re winning because they don’t have to. Prevention is the key. That’s what I want for Cambridgeshire too. But after decades of underfunding and some poor past choices, we’ve got a lot of catching up to do. We’re starting to reverse that, with record investment into resurfacing, surface dressing, and preventative work but it’s going to take time. And in the meantime, we still have to deal with tens of thousands of potholes every year.

On average we repair between 40,000 and 60,000 potholes annually, using a combination of traditional crews and Dragon Patcher machines, spending around £3 million annually.

But that’s just a fraction of our overall highways maintenance budget. The vast majority goes on longer-term repairs that prevent potholes in the first place. This year (2024/25), we’re investing:

£30.7 million in structural and preventative carriageway maintenance

£7.2 million on structural and preventative work for footways and cycleways

(Myth Buster: No we can’t spend the money Active Travel England gives us for new active travel routes on maintenance. Not surprisingly Active Travel England ringfences it to Active Travel projects!)

We’re responsible for looking after a vast network:

4,519 km of roads

2,710 km of footways (including 277 km not adjoining roads)

41 km of designated cycleways

3,244 km of other public rights of way

For now, here’s how we currently fill potholes and what we’re doing to improve it.

How Do We Know About Potholes?

We find out about potholes in two main ways:

Public reports

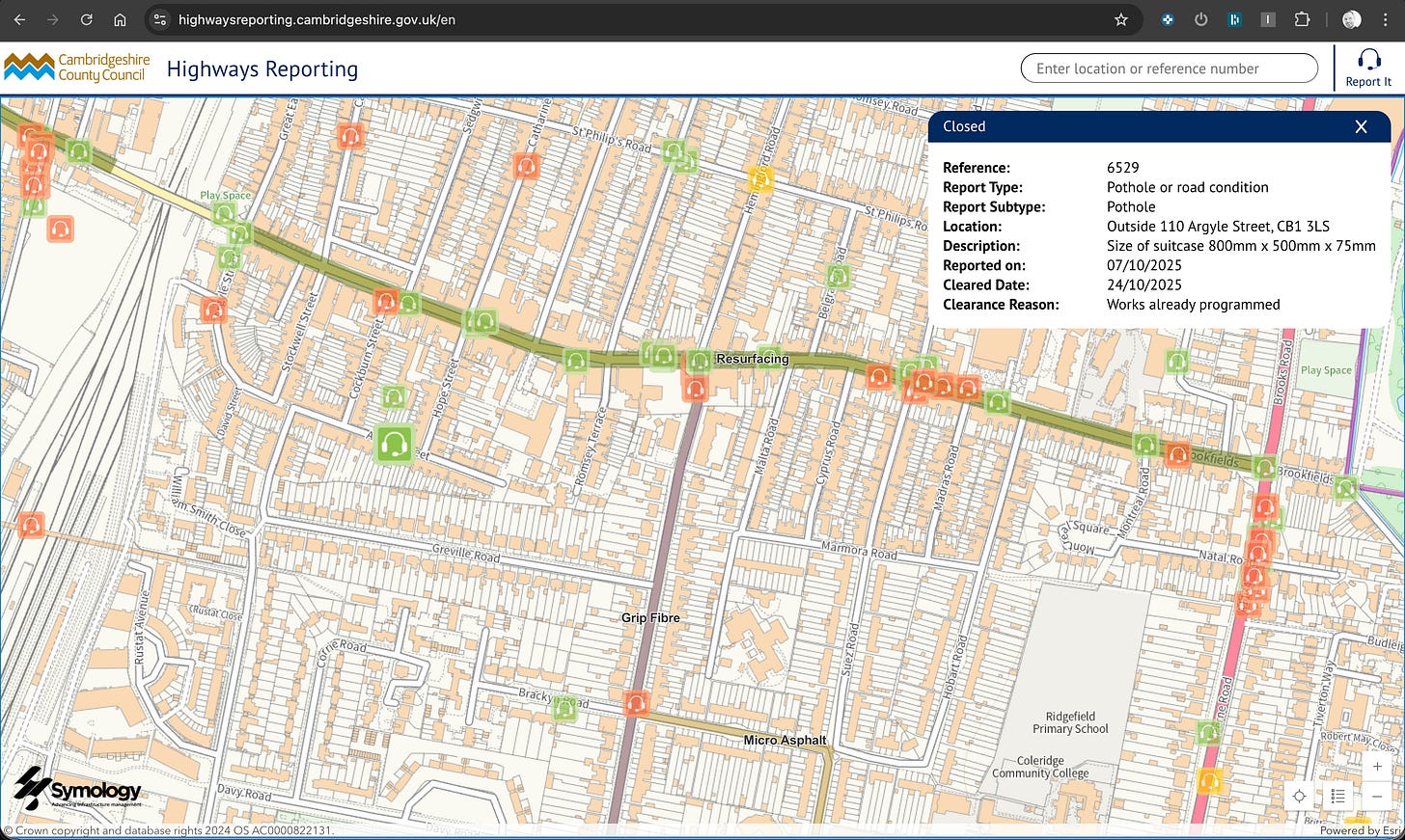

About a third of pothole repairs start with a report via our Report It tool. Anyone can report a defect. These appear as orange on the map while awaiting inspection.

Highway inspections

Two thirds of our repairs come from our trained inspectors who regularly walk or drive every part of the network. These inspections follow a scheduled frequency depending on road type:

Strategic routes, main distributors, secondary distributors and Active Travel Category 1 & 2 (CW1–CW3): Monthly

Link Roads (CW4): Quarterly

Local access roads (CW5): Annually

Footways (FW1–FW3): Monthly

Other footways and shared paths (FW4–FW6): Annually

Remote cycleways and key walking routes (Active Travel routes): Twice per year

What Happens When a Pothole Is Reported?

All faults, whether from public reports or inspections, go into our Aurora Highways Asset Management System.

Aurora assigns the report to an inspector. If it meets our investigation levels, the inspector will visit the site and carry out a risk assessment.

Standard investigation levels:

Carriageways:

40 mm depth and 75 mm width for a pothole; 40 mm depth and 20 mm width for a crack

Cycleways:

25 mm depth and 75 mm width for a pothole; 25 mm depth and 20 mm width for a crack

Footways:

20 mm depth or 20 mm of vertical movement in a slab

Risk Assessment Outcomes:

Not at intervention level – we’ll continue to monitor it, or

Repair required under one of the following categories:

Category 1a: Emergency – immediate make-safe. Repaired within 5 days

Category 1b: High-risk but not urgent – permanent repair within 21 days

Category 2: Low-risk – added to the programme for future repair

These intervention levels were set a long time ago and reflect the reality of limited revenue budgets. We’re currently reviewing whether they can be updated. Personally, I believe many small potholes eventually become large ones, so filling them earlier may save money long-term but the data needs to back that up.

Once inspected, the pothole is marked with spray paint:

Yellow: urgent (Category 1)

White: longer response time (Category 2)

Thanks to our new system, inspectors can now order the repair directly using tablets by the side of the road. Until recently, they had to return to base, a major inefficiency we’ve now fixed.

Historically, you’d also have seen reports on the Report It tool closed at this point, as there was no integration with our contractor system. Infuriating. Now, you’ll get an email notification that works have been ordered, and the pin on the map will turn yellow.

If the defect is larger than 1m², it’s classed as a patch rather than a pothole and goes into a slower, more complex process. We’re working to simplify this, as our current contract treats patches and potholes very differently. We’re also reviewing how to avoid ending up with “pothole quilts” or areas where multiple small repairs are done over and over. It’s bad value and bad for road users. Unfortunately, due to the systems and contracts we have in place, fixing this isn’t anywhere near as simple as it should be!

How Do We Fill Them?

We have a historic contract with M-Group to carry out pothole repairs. I should add that both we and M-Group recognise the contract is lacking and doesn’t represent the best efficiency for either party. The contract expires in 2027, and we’re actively planning for the future. More on that in a separate post though.

Most repairs are done via one of three methods:

1. Temporary Make-Safe Repair

Used when: the pothole is dangerously unsafe

Method: Cold-mix tarmac poured in

Speed: Very fast

Downside: Not durable—can crumble quickly and often looks like a ‘bodge job’

Purpose: Prevent harm while we queue up a permanent fix

2. Dragon Patcher

Type: Fast, mobile, semi-automated machine

Cost: ~£33 per pothole

Usage: 50–70% of repairs

Process: Dries the hole with a flame, sprays hot bitumen and aggregate, then rolls over it

Pros: Doesn’t need traffic lights or big crews; great for rural roads; cost-effective—roughly ½ to ⅓ the cost of a traditional repair

Cons: Struggles in bad weather, tight spaces, or urban areas with parked cars or cyclists due to loose chippings

3. Traditional Repair Crew

Method: Crew cuts out the area, cleans it, fills with hot bitumen, tamps, and band-seals edges

Cost: ~£80 per pothole

Coverage: 30–50% of repairs

Pros: Most durable and neatest

Cons: Needs traffic management, bigger crew, slower and more expensive. Crews also sadly face occasional abuse, which is unacceptable—and they’re exposed to more danger by being in the carriageway

Once complete, the pothole is marked green on the Report It map and the original reporter is notified.

How Do We Check Quality?

After a repair is logged as complete, a percentage are randomly selected for follow-up inspection by a highways officer. If a repair fails, we raise a dispute with the contractor and we don’t pay for substandard work.

Historically, the County Council wasn’t great at checking quality. That’s changed. We’ve now got much more robust systems in place, and Aurora ensures checks are tracked and carried out.

Any public complaint also triggers a reinspection. While the number of poor-quality repairs is small, they’re highly visible, so we take them seriously. If you see a bad repair, please do tell us. Repairing ~50,000 potholes a year in all conditions means they’re not all perfect, but where there’s substandard work we can and do hold our contractor accountable.

Reporting & Data

When I first took on this job, I was amazed by how little we knew about the state of our roads. Often, the first we’d hear about a problem was when complaints reached a tipping point.

We’ve changed that. We now track:

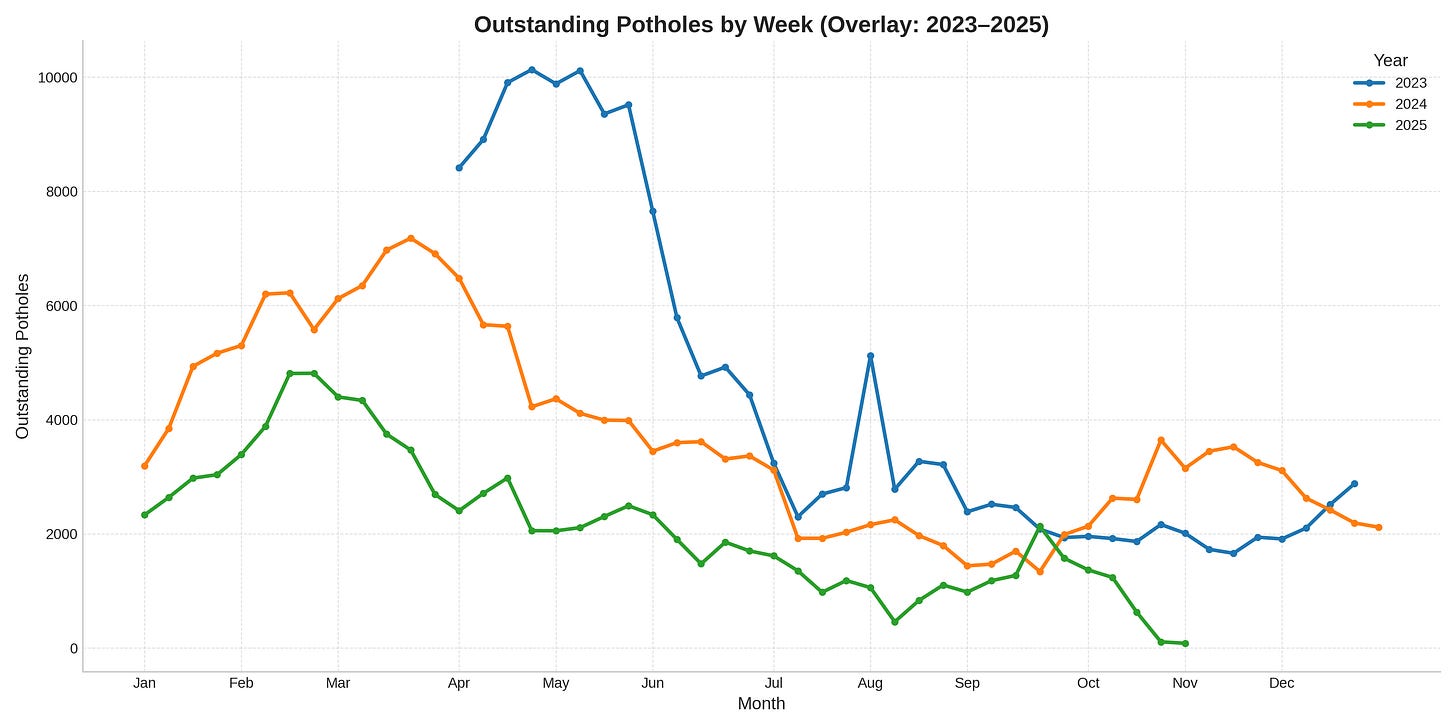

Weekly totals of potholes reported, outstanding, and completed

Monthly trends (We’ve found February is nearly always the worst)

Correlation with weather events (After particularly cold weather we almost always have an influx)

This helps us plan resources, including hiring extra crews during peak times.

We’re also now integrating condition data from LiDAR-equipped survey vehicles, which provide a detailed and objective measure of road surface condition. These surveys help us spot problems before potholes even form.

Looking ahead, we’re exploring real-time data sources—from vehicle telematics to crowd-sourced cyclist reports and AI-powered defect detection. The goal is a live dashboard of road condition across the county, helping us direct crews where they’re most needed and flattening any pothole peaks. We’re also analysing repair costs by area to better target our budgets and ensure value for money.

What We’re Working On

Better data – Aurora unlocks better insight into road condition, repair quality, and pressure points

Smoothing pothole vs patch – Currently separate processes, but we’re working to make this seamless

Quilt prevention – New guidance to reduce patchwork and fix whole problem areas

User-focused intervention – Reviewing thresholds for key users like cyclists and school routes and making sure we have the right interventions in the right place for the right users

Pavements – Often overlooked, but vital. We’re improving how we track and prioritise footway repairs

Community help – We’re exploring whether volunteers can help us fill minor holes in their own communities

New tech – We regularly trial new kit (like the JCB Pothole Pro). We’ve yet to find anything better than Dragons and our manual crews though!

Environmental efficiency – Tackling climate change is key and we’re always looking at how we can be more environmentally efficient. All our Cambridgeshire Highways vehicles now run on HVO and we’re making a lot of progress using recycled materials

In Summary

We’re working hard to streamline how we handle repairs, but the real long-term solution is prevention and that’s where the majority of our investment is now going.

Got questions or ideas? Hit me up in the comments. And if you’re from another local authority and think you’ve cracked a better way to do things, or just want to talk potholes over a beer, I’d love to hear from you!

Hi Alex,

Appreciate the post and it's interesting to understand the background.

Can I highlight 2 particular cases.

Clifton Road, near 50 Clifton road. Someone has logged 17671 3 weeks ago. It's flooded and now someone has left a traffic cone in it so drivers don't even think about driving over it.

Shelford road, Trumpington end has had multiple reports for dozens of potholes for months and drivers are now swerving to avoid them all.

Dear Alex,

Thank you for the transparency with your Substacks. I don’t envy your position, given the limited financial room local government has due to spending on statutory requirements and a large road network. With that said, I would like to ask a few hard questions, and raise a few specific issues.

Qs:

1. Do you know if the rate of deterioration of the highways exceeds the rate at which they are repaired? Can you quantify this, as it seems the most important indicator of successful maintenance program? If the deterioration rate exceeds the maintenance rate, you are losing the battle. Equal is treading water. My feeling is, despite your teams’ best efforts, that the rate of deterioration exceeds the repair rate, driving people’s frustration as they see the highways getting progressively worse.

2. Have you looked at the rate of injuries at A&E due to cyclists being injured from hitting potholes – has it increased recently? Some are very dangerous when it is dark and filled with water. At what point does it become a public health issue? (A disease causing a cluster of broken bones would merit an outbreak investigation, why not potholes?)

Issues:

1. Have you travelled down Cambridge road/Tunwells lane/ London road through Great Shelford and Stapleford recently? It is by FAR the worst road condition I have ever seen. There is a resurfacing scheduled for only a small part of it (Tunwells lane), but that is far too short to cover the craters along this road. Please do have a look yourself, because it really is terrible – could you look at extending the resurfacing works while they are there, please.

2. Many of the road signpost in South Cambs have rusted through completely and have collapsed or are about to. This suggests they do not comply to the corrosion resistance standard as laid out in BS EN 12899-1, and the procurement was likely incorrect? They should surely be galvanised steel with root protection and this wouldn’t be a problem? Is there a plan to replace these collapsing signposts? Does your team know the extent of the problem?